A Day in the Life at Brightlands Chemelot with our Head of Operations

Pictured is Marc (right) on a break from HAZOP meetings, with Itero team members Sieto Schenkel (left), Project Manager, and David Nessbach (middle), Project Engineer.

We sat down with Marc Eggen, our Head of Operations at Brightlands Chemelot Campus, to talk about his career in chemical engineering, what drew him to innovative plant development, and how he’s helping bring Itero’s industrial demonstration plant to life. With decades of hands-on experience across the globe, most recently on the Chemelot Industrial Park with innovative plants, Marc shares what a typical day looks like, the challenges of building from the ground up, and what excites him most about the path ahead.

How did you first get into chemical engineering and operations?

As a child, chemistry was like magic to me: seeing liquids change colour or smoke suddenly appear as if from nowhere sparked a deep desire to understand more. This excitement has stayed with me over the course of my career in research and development, where I focused on optimising and troubleshooting technology which applies chemistry to develop new materials. I’ve brought this curiosity and strong technological background into my work managing operations.

What advice would you give to someone just starting out in operations or chemical engineering today?

My advice to young people would be to stay true to your passion, explore your field, and engage in work you can truly put your heart and soul into. Don’t be afraid of failure, it’s part of the journey and one of the greatest sources of learning.

You’ve had a lot of experiences in building plants for innovative technologies, what draws you to wanting to work in innovation? What are the most interesting aspects?

Innovative projects always follow a bumpy road. Compared to more established technologies, the journey has more unexpected turns. This can include moments when you are truly challenged - when you learn the most about yourself and confronted with your own weaknesses. The difference between success and failure for a startup depends on how an organisation deals with these inevitable setbacks. Do we solve problems together and truly listen to one another, or do we become defensive and individualistic? I’ve seen both approaches, and they made a huge difference in the future trajectory of these projects.

How has your background helped you tackle the challenges of building this first-of-its-kind demonstration plant?

Over the last decade I’ve worked at multiple early-stage companies each at a different point in the journey of developing an innovative new idea. Itero is creating something from the ground up, and I get to develop both the technical and organizational structure to achieve that. I’ve learnt that everything starts with safety and compliance. Once those structures are in place, you have the stability needed to manage the technical and organizational challenges that come with scaling new technology.

At one of my previous roles, everything had to be created from scratch: operators had to be hired, procedures developed, and the plant itself had to meet a wide range of regulations and safety standards. Equipment would fail, supplies had to be sourced, and the process itself wasn’t expected to run smoothly at first — someone had to step in and solve those issues.

When you're one of the only people on the ground, working side-by-side with the operators, it quickly becomes clear that you must take the initiative. Unlike in larger organisations, you can't rely on existing departments or support structures. At times, you don’t know the best way forward, but each success is deeply satisfying, and once everything is in place, you feel genuinely proud of what you’ve accomplished.

My background has helped me anticipate what to expect in these early phases — and more importantly, how to build a strong operational foundation. In this early phase of our chemical recycling technology, every single contribution is tangible and impactful, not just on the technology but also on the company culture and the design of work processes.

What does a typical day at Itero look like for you?

I’ve grown used to arriving very early at the Brightlands campus—well before 7 a.m., while the parking lot is still empty. This quiet window lets me focus on the most urgent operational matters without interruption.

Right now, while the plant is still in development, my focus is on building the structures needed to ensure compliance with all applicable regulations and to create a safe working environment. It’s a significant and often underestimated part of the process.

In addition, I’m already involved in reviewing the process and supporting areas that still require solutions, for instance recently working to improve the efficiency of our wastewater management. I’m preparing for future maintenance needs, setting up partnerships with service providers, and planning how we’ll staff the plant. That includes laying the groundwork for all core functions: production, safety, logistics, procurement, materials analysis, finance, HR, and IT.

What part of your workday do you enjoy most?

One moment I enjoy is lunch at the Brightlands restaurant with colleagues. During lunch, work takes a back seat for a bit. I believe how we interact with one another lays the foundation for achieving anything together. These social moments strengthen team connections, allowing me to best support my colleagues in performing their work.

How does your role contribute to the company's mission of creating a sustainable and circular carbon economy?

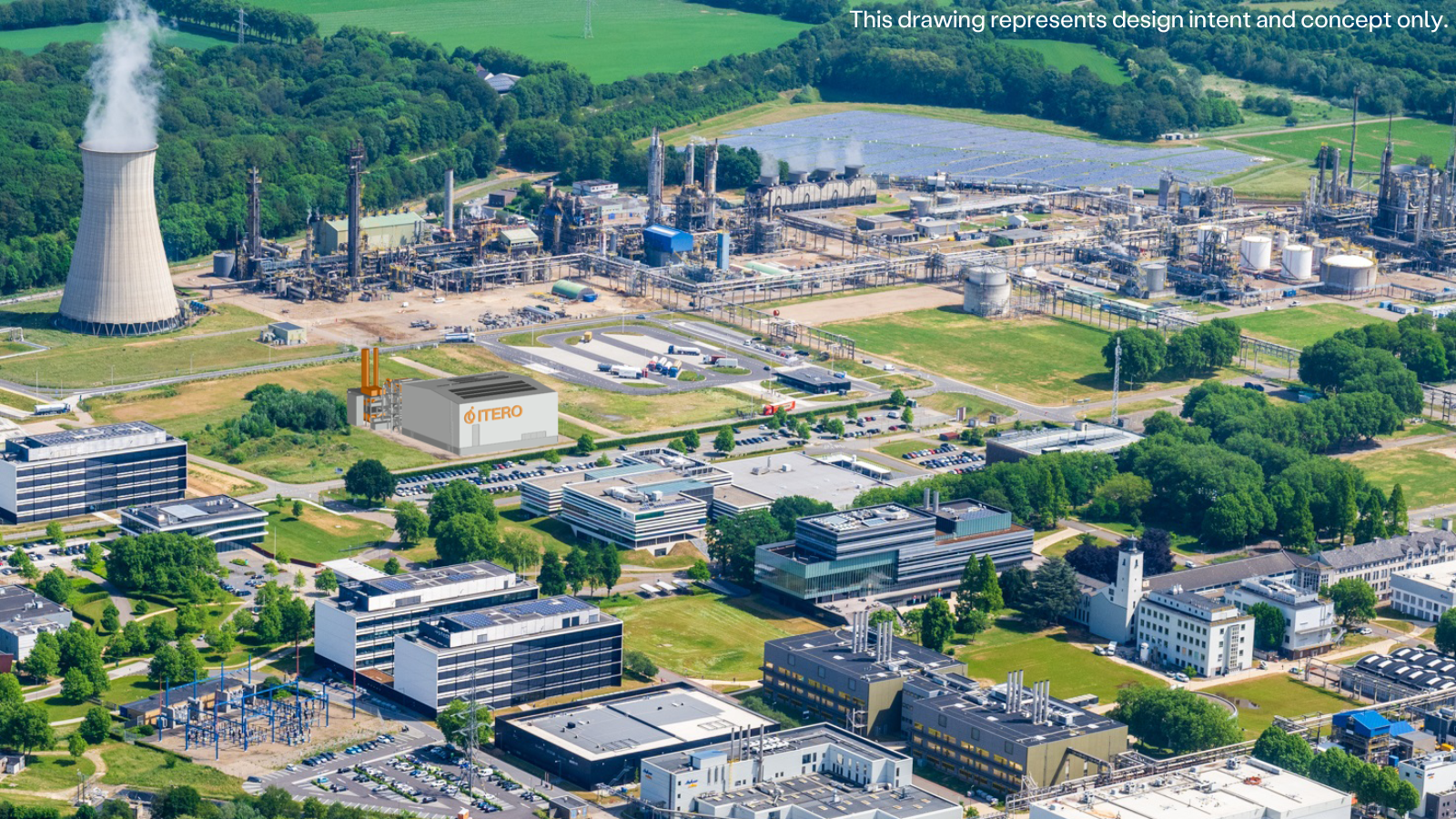

My role at Itero is about doing—it's hands-on, with a broad organizational scope. I help organize and execute the development of our Brightlands Chemelot plant, which must operate within a complex framework of conditions and ambitious goals.

Fortunately, we have a strong team handling the plant’s design and construction. As we move closer to the construction phase, I’m looking forward to taking on a more active role in bringing the plant to life. When completed, the plant will represent a major step forward in closing one loop in the plastic life cycle by recycling previously unrecyclable plastics at a new scale, reducing the amount of plastic that currently ends up in landfill and incineration while preventing further oil extraction for plastics production. will represent a major step forward in closing one loop in the plastic life cycle by recycling previously unrecyclable plastics at a new scale, reducing the amount of plastic that currently ends up in landfill and incineration while preventing further oil extraction for plastics production.

Once completed, the Brightlands Chemelot demonstration plant will process 27kt per annum of waste plastics, 5x the plastic waste collected by the city of Maastricht per year, while offsetting over 20kt per annum of fossil resources, the equivalent of offsetting nearly 500 barrels a day

Why is the Netherlands a great place for companies like Itero to grow?

The Netherlands is at the forefront of sustainability, with strong government support and a vibrant ecosystem of companies developing high-impact technologies. There’s a robust structure in place to support technological evolution, not only through government support but also through the efforts of companies currently engaged in areas with high potential for climate gains. There’s a clear economic argument for investing in sustainability: sustainable technology development lays the foundation for future industries, and the Netherlands is positioning itself to lead that charge.

What challenges have you encountered so far – and what’s coming next?

Now, much of my work is about preparation and planning. It’s straightforward in many ways because the construction is in capable hands of our Project Manager. Our core technology is also very well defined, having been operational at our West London Pilot Plant since 2020.

My real challenge lies ahead: ensuring that everything is ready on time so the plant can be brought online within the defined parameters: safely, with trained personnel, and running efficiently. The plans and groundwork I’m currently focused on will need to prove their value during that critical phase.

What are you most looking forward to in 2025?

I’m looking forward to the moment the official go-ahead for construction is given, which we expect to happen later this year. It’s always a significant milestone because that will be the point when things become concrete, and we can start making real commitments. It’s the moment when you know the plans you've developed begin to go into action, and you can begin bringing everything to life.

Read more about our plans for our Brightlands Chemelot demonstration plant.